Bioreactor Definition Bioreactor Design Bioreactor Principle Parts of the bioreactor and their function 1. Fermenter Vessel 2. Heating and C...

Bioreactor Design

Bioreactor Principle

Parts of the bioreactor and their function

1. Fermenter Vessel

2. Heating and Cooling Apparatus

3. Aeration System

4. Sealing Assembly

5. Baffles

6. Impeller

7. Sparger

8. Feed Ports

9. Foam-Control

10. Valves

11. Controlling Devices for Environmental Factors

12. Use of Computer in Fermenter

Types of bioreactor

1. Continuous stirred tank fermentor

2. Airlift fermentor

3. Bubble column fermentor

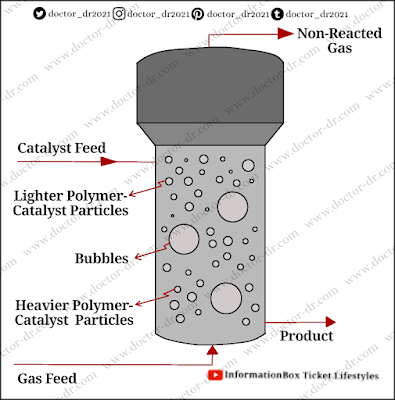

4. Fluidized-bed fermentor

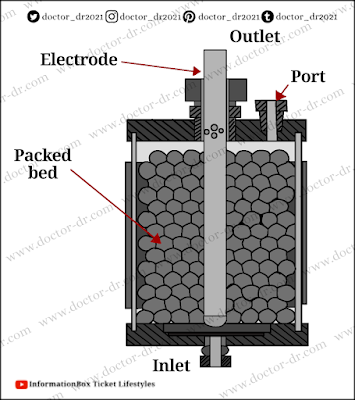

5. Packed bed fermentor

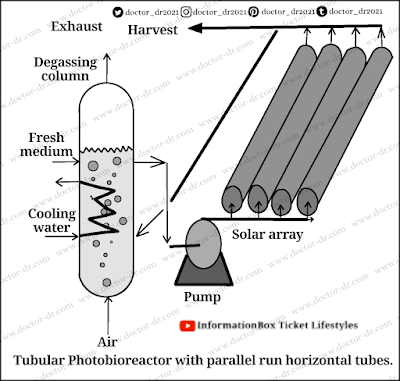

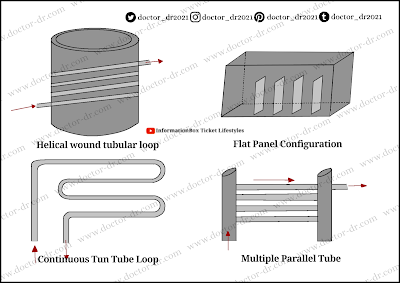

6. Photobioreactor

7. Membrane bioreactor

Applications of bioreactor

Limitations of bioreactor

Bioreactor Definition

An example of a fermentation vessel is a bioreactor, which is employed in the synthesis of numerous chemicals and biological processes. In order to remove the waste biomass of cultivated microorganisms as well as their products, it is a closed container with suitable arrangements for aeration, agitation, temperature control, and pH control.

The following should be included in a bioreactor:

- Regulation of parameters including temperature, pH, pressure, aeration, nutrient feeding, and liquid levelled.

- Agitation (for mixing cells and medium);

- Aeration (aerobic fermentors); for O2 supply

- Withdrawal of cells/medium,

- sterilisation, and maintenance of sterility

Biomass, metabolites, and antibiotics are produced in bioreactors.

Bioreactor Design

A bioreactor's design and method of operation are based on the creation of an organism, the ideal circumstances needed for the formation of the intended product, the value of the product, and its scale of production.

The productivity of a bioreactor may be increased, and it can produce goods of greater quality for less money.

A bioreactor is a device that includes a number of features, including an agitator system, an oxygen delivery system, a foam control system, and a number of other systems, including sampling ports, cleaning and sterilisation systems, lines for charging and emptying the reactor, and systems for controlling temperature and pH.

The following crucial characteristics must exist in the substance used to make a bioreactor:

It should not be corrosive.

- Toxic compounds shouldn't be added to the fermentation medium.

- It must be able to withstand the steam sterilising procedure.

- It need to be capable of withstanding high pressure and enduring pH variations.

- Depending on the use, the bioreactor's sizes might vary significantly.

From the microbial cell (few mm3) to the shake flask (100-1000 ml) to the laboratory-size fermenter (1-50 L) to the pilot level (0.3-10) to plant scale (2-500 m3) for big volume, some bioreactors are built for small scale fermenters and some for large scale industrial applications.

Bioreactor Principle

- In order for microorganisms to develop optimally and create metabolites for the biotransformation and bioconversion of substrates into desired products, the bioreactor is essential to any biochemical process.

- Reactors can be designed or created based on the needs of the organisms employed for growth.

- Reactors are devices that can be used to turn materials with biological origins into palatable goods.

- They can be used to produce different enzymes and carry out other bio-catalysis procedures.

Parts of the bioreactor and their function

- These reactors have been built to manage parameters including temperature, pH, flow rates, aeration, foam control, and agitation rates.

- The amount of sensors and control devices included into a particular bioreactor determines how many parameters can be monitored and managed.

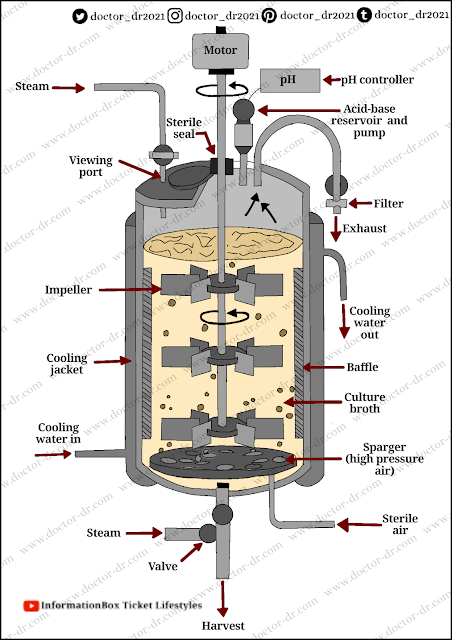

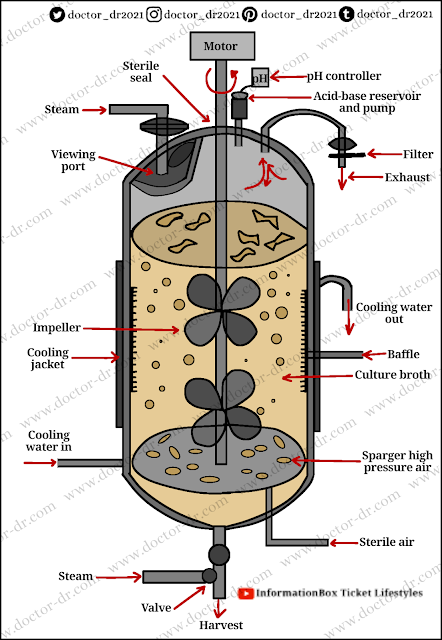

- Before creating a fermenter, keep in mind the additional considerations listed below and illustrated in the figure below.

1. Fermenter Vessel

- A fermenter is a large cylinder that is top- and bottom-closed and is linked to other pipelines and valves.

- The vessel's design enables it to function in a controlled environment.

- There are two common types of fermenter vessels: glass and stainless steel.

- Small-scale companies often employ the glass vessel. It is non-toxic and resistant to corrosion.

- Large-scale companies employ stainless steel vessels. It can withstand corrosion and pressure.

2. Heating and Cooling Apparatus

- A cooling jacket that supplies cooling water and seals the fermentor vessel's outside is installed.

- In most cases, heat is produced using thermostatically regulated baths or internal coils, and excess heat is dissipated using silicone jackets.

- Sterilization of the nutrient medium and removal of heat produced during fermentation in the fermentor require the use of a cooling jacket.

3. Aeration System

- One of the fermentor's key components is the aeration system.

- To maintain optimum aeration and oxygen availability throughout the culture, a suitable aeration system must be used.

- To ensure proper aeration in a fermentor, it has two different aeration devices (sparger and impeller).

- The stirring achieves two objectives: it assists in mixing the gas bubbles through the liquid culture medium and it aids in mixing the microbial cells through the medium, ensuring that they all have uniform access to the nutrients.

4. Sealing Assembly

- To ensure appropriate agitation, the stirrer shaft is sealed using the sealing assembly.

- In the fermenter, there are three different types of sealing assemblies:

- sealed packed gland

- Mechanical seal

- Magnetic drives

5. Baffles

- Baffles are placed into fermenters to reduce vortices and increase aeration.

- It comprises of metal strips that are radially fastened to the wall.

6. Impeller

- The uniform suspension of microbial cells in various nutritional media is achieved using impellers.

- They consist of motorised impeller blades mounted on the lid.

- When it comes to lowering the size of air bubbles and distributing them evenly throughout the fermentation media, impeller blades are crucial.

- The fermenters employ variable impellers, which are divided into the following categories.

- Disc turbines

- Open variable pitch turbine

7. Sparger

- In order to provide sterile air to a fermentation tank, a sparger is utilised. It aids in giving the vessel the correct aeration.

- Pressurized air is discharged through tiny 5–10 mm holes located in the sparger pipes.

- There are three varieties of sparger.

- Porous sparger

- Sparger nozzle

- combined agitator and sparger

8. Feed Ports

- They are employed to replenish the fermentor with nutrients and acid or alkali.

- Silicone tubes serve as feed ports.

- The products are sterilised in-place before being removed or added.

9. Foam-Control

- It's crucial to keep the amount of foam in the vessel to a minimum in order to prevent contamination.

- Foam sensor and a control unit work together to regulate foam.

- The fermentor has a foam-controlling mechanism attached to the top with an entrance into the fermentor.

10. Valves

- In the fermentor, valves are used to regulate the flow of liquid.

- Globe valves, butterfly valves, ball valves, and diaphragm valves are the most common types of valves used.

- The air and pipe layout includes a safety valve that can function under pressure.

11. Controlling Devices for Environmental Factors

- To regulate environmental factors like temperature, oxygen concentration, pH, cell mass, levels of vital nutrients, and product concentration, a variety of devices are used.

12. Use of Computer in Fermenter

- Fermentors are typically used in conjunction with contemporary automated and semi-automated computers and databases for an effective process, monitoring, and data collection.

Types of bioreactor

The types of fermentors (bioreactors) that are frequently used in industries are

1. Continuous stirred tank fermentor

- In a continuous stirred tank bioreactor, one or more agitators are supported by a central shaft that is cylindrical and powered by a motor (impellers).

- Improved gas distribution throughout the vessel is made possible by the sparger and impellers (agitators).

- A stirred tank bioreactor may run continuously in the fermentor, temperature control is simple, construction is inexpensive, operation requires little training, and cleaning is straightforward.

- It is the type of industrial bioreactor that is utilised the most.

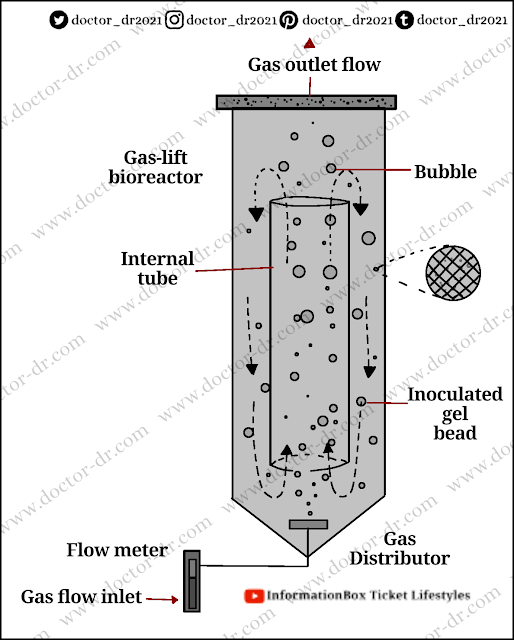

2. Airlift fermentor

- Typically, gas-liquid or gas-liquid-solid contact devices employ the airlift reactor. A tower reactor is another name for it.

- In a bioreactor with an airlift system, the fluid volume is divided into two zones to enhance oxygen transfer, circulation, and force equalisation.

- Only one zone of a two-zone system receives gas sparging. The riser is the zone where gas is sparged, whereas the downcomer is the zone where gas is not sparged.

- Aerobic bioprocessing technology uses airlift bioreactors because they can deliver a regulated liquid flow in a recycling system employing pumps.

- This equipment's simplicity of design—it has no moving components or agitators—ease of sterilisation, minimal energy needs, and inexpensive price are just a few of its benefits.

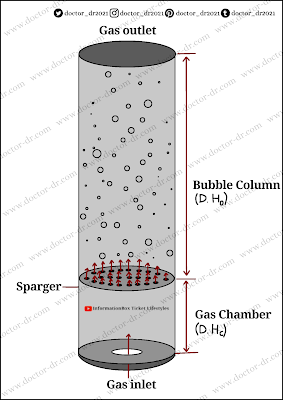

3. Bubble column fermentor

- A cylindrical vessel with a gas sparger that propels gas bubbles into a liquid phase or a liquid-solid suspension makes up the bubble column fermentor.

- By use of perforated pipes, plates, or metal micro porous spargers, air or gas is injected into the base of the column.

- The mixing of O2 and other performance variables are significantly influenced by the fluid's rheological characteristics and gas flow rate.

- Internal devices including horizontal perforated plates, vertical baffles, and corrugated sheet packings are installed within the vessel to optimise mass transmission and change the vessel's fundamental design.

- These reactors are inexpensive to operate, have simple design, and need little maintenance.

- In biochemical procedures like fermentation and biological wastewater treatment, bubble columns reactors are employed. Numerous chemical, petrochemical, and biochemical industries also employ it.

4. Fluidized-bed fermentor

- In fluid bed bioreactors, smaller particles are put into beds. This avoids issues with packed bed reactors such clogging, excessive liquid pressure drop, channelling, and bed compaction.

- Reactants are injected into the reactor by a distributor pump after the catalyst is placed on the bottom of the reactor to fluidize the bed.

- Small particles that flow with the fluid and immobilise the cells in these reactors improve mass transfer, oxygen transfer, and nutrient delivery to the cells.

- Reactions involving fluid-suspended biocatalysts, such as immobilised enzymes, cells, and microbial flocs, can be carried out in the bioreactors.

- In comparison to other catalytic reactors, its key benefits are the capacity to maintain uniform temperatures, simple catalyst replacement and regeneration, continuous and autonomous operation, and shorter gas–solid contact times.

5. Packed bed fermentor

- A packed bed fermentor is a solid particle matrix with a biocatalyst on or within it.

- Either the submerged mode (with or without aeration) or the trickle flow mode can be used to operate it.

- Packed bed reactors, also known as fixed bed reactors, are frequently employed in chemical processing procedures including absorption, distillation, stripping, separation processes, and catalytic reactions.

- In packed-bed bioreactors, the substrate is supported by a sieve through which air is introduced.

- This reactor has many advantages, including a high catalyst conversion rate, simplicity of use, low construction and operating costs, increased reactant and catalyst contact, and the capacity to operate at high temperatures and pressures.

6. Photobioreactor

- A photobioreactor is a specially designed fermentation machine that either receives natural light from the sun or artificial light.

- The tubes or flat panels are composed of light receiving devices and are constructed of glass or, more frequently, transparent plastic.

- The medium of this bioreactor may be pumped via solar receivers using centrifugal pumps or airlift pumps.

- Photo-bioreactors are typically run continuously at a temperature between 25 and 40 °C.

- Microalgae and cyanobacteria are grown in photobioreactors for their photosynthetic production of compounds such astaxanthin and beta-carotene.

7. Membrane bioreactor

- This system removes organics and suspended particles as well as high nutrient levels by combining conventional treatment with membrane filtration.

- This system uses an aerated biological reactor with immersed membranes. The membrane's pores have sizes ranging from 0.035 microns to 0.4 microns.

- The advantages of this bioreactor are increased with pure oxygen, leading to even faster biological treatment systems that offer compact control of COD, microorganisms.

Applications of bioreactor

Some important applications of the bioreactor are:

|

Type of bioreactor |

Applications |

|

Stirred tank fermenter |

Antibiotics, citric acid, Exopolysaccharides, cellulose,

Chitinolytic enzymes, Laccase, Xylanase, Pectic, and pectate lyase, Tissue

mass culture, Lipase, Polygalacturonases, Succinic acid |

|

Bubble column fermentor |

Algal culture, Chitinolytic enzymes |

|

Airlift fermentor |

Antibiotics, Chitinolytic enzymes, Exopolysaccharides,

Gibberelic acid, Laccase, Cellulase, Lactic acid, Polygalacturonases, Tissue

mass culture |

|

Fluid bed fermentor |

Laccase |

|

Packed bed fermentor |

Laccase, Hydrogen, Organic acids, Mammalian cells, |

|

Photobioreactor |

Wastewater treatment, water quality management, remediation of

contaminated soil |

|

Membrane bioreactor |

Alginate, Antibiotic, Cellulose hydrolysis, Hydrogen production,

Water treatment, VOCs treatment |

Limitations of bioreactor

|

Types of bioreactor |

Limitation |

|

Stirred tank fermenter |

High shear stress |

|

High power consumption |

|

|

Moving internal parts |

|

|

Bubble column bioreactor |

Low photosynthetic efficiency |

|

Airlift |

Non-uniform nutrient supply |

|

Insufficient mixing |

|

|

High viscosity can limit bulk circulation |

|

|

Fluid bed fermentor |

Particle (breakup) is common |

|

Increased reactor vessel size |

|

|

Bubbling beds of fine particles are difficult to predict and are

less efficient. |

|

|

Pipe and vessel walls erode due to collisions by particles |

|

|

Packed bed bioreactor |

Undesired heat gradients |

|

Poor temperature control |

|

|

Difficult to replace the catalyst |

|

|

Photobioreactor |

Salability problems |

|

Require temperature maintenance as they lack evaporative cooling |

|

|

Periodic cleaning due to light exposure |

|

|

Need maximum light exposure |

|

|

Membrane bioreactor |

Biofilm overgrowth leads to periodic cleaning |

|

The membrane can rupture at high flow rates |

No comments